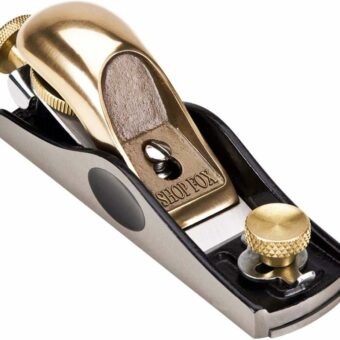

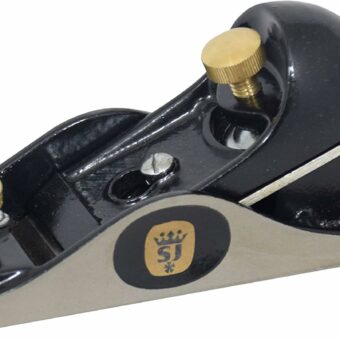

Description

Price: $87.95

(as of Oct 30, 2024 12:43:55 UTC – Details)

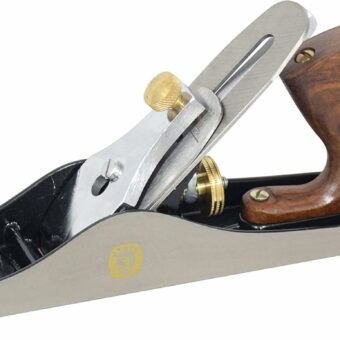

This Rabbet Plane is finely cast and precision milled to cut perfect rabbets in about the time it takes to set up a jointer or shaper. There are two cutter positions, one for normal rabbeting work and a forward position for planing into corners. Includes an adjustable fence that can be used on either side of the plane, threaded depth adjusting screw for precise control of the plane iron, depth stop and edge spur for crisp edges. Sole measures 8-1/2″ long by 1-1/2″ wide.

Finely cast and precision milled

Package dimensions: 6″ x 10.5″ x 2.7″

Approximate weight: 4.25 lbs

Stan Ferris –

WORKS GREAT

I honed the blade and cut some 1/4″ rabbets and it worked great! Watch where you put your free hand along the side. I kept cutting my finger by not being careful and resting my left hand right where the edge of the blade stuck out. Operator error!

Mister Fenster –

It works, but it’s not golden. (Well, actually it’s black but that’s another story.)

All the bad things you can read in the other reviews are true of the plane I received. The fence is crooked, the blade is in bad condition, the machining is far from perfect, the nicker is nothing special. I wiped the thing down with light solvent to get the oil off, sharpened the blade, and took the thing to the shop for a quick test. It worked just fine. The grease used to keep the unit from rusting during shipping made the blade slip around. There are better rabbet planes out there, but they cost about 3 times as much. If you’re looking for the very best in tools, this unit may not be for you. If you’re looking for something that’s functional, and you can tune a plane and make it work, the savings will be all yours.

Amazon Customer –

Good value — I think — still early in use; had to harden blade to get it to hold an edge

Well made for the most part– the machined surfaces are flat (sole, offset arm, right side) and perpendicular; I have two areas of concern to discuss: there is a small cutter on the right side which is used to scribe(cut) a small channel in the corner of the rabbet — shown in the fourth pic; I had to work on this to get the screw recessed adequately so that it is smooth to that side. As it arrived it projected into the right side cutting area (think of it as the vertical side of the rabbet you’re cutting) and it scraped a non-desireable effect in the rabbet wall. This cutter can be rotated by loosening the screw and then does not perform the scribe function but the screw projected anyway. I had to carefully enlarge the hole of the cutter to get the screw further into the recess of this cutter element. It took about an hour to do this using a appropriate drill bit and a diamond plate.The second concern is the blade didn’t hold an edge and had nicks in it after sharpening; I heated blade edge on cutter side to red hot, quenched in oil and so far blade holds an edge; in last pic the sharpened edge shows no nicks

Todd Kehoe –

Great Plane

This thing is great. Can’t wait to plane something else!

Michael J –

Quality control is highly variable at best

There’s a lot to like about this plane, and if they’d only paid a little more attention to detail, it would have been a fine tool. I bought mine direct from Grizzly for significantly less than the price here, so I was suspicious as to how good it could be, but after reading the positive reviews here I decided to risk it.The good bits: The body is machined well, with a flat base and sides that are perpendicular. The Blade takes a good edge with some work. But that’s where it ends.The fence not perpendicular to the blade, which means it’s just about impossible to cut a straight rabbet. The spur/nicker blade isn’t a blade at all- it doesn’t have a edge, and requires a good deal of grinding to make it work. It also fits very loosely (and too deeply) in the recess cut for it. The front mouth is cut perfectly, but the rear mouth- the one you’re using 99% of the time- has an abrupt shoulder that doesn’t properly support the blade, and so it chatters on cross grain. And the depth stop won’t stay in place unless you crank the brass nut down with a pair of pliers.I was tempted to try and fix these problems, but I have no way of extending the sole, or fixing the alignment of the guide rods, which would require welding and milling, or at a minimum, making an add-on wooden fence that’s planed parallel to the sole. I sent it back to Grizzly, and a week and a half later I got a replacement. This one was covered in heavy grease, which makes me wonder if the first one I received wasn’t a repackaged return. I cleaned it up with mineral spirits, gave it a coat of wax to protect it from rusting, and honed the back of the blade.This one fixed two of the three problems of the first unit: The mouth is properly cut, and the guide rods are now perpendicular to the sole, so it cuts properly. The cross-grain spur is still worthless, but there are ways to deal with that. I took it to the bench to try it out on some scrap pine. My first try generated a lot of crumbly chips that quickly clogged the mouth of the plane. It was grating the wood, not cleanly cutting it. Back to the workbench, where I gave the blade a closer look at the edge- it was pretty rough, and ground to a 25 degree bevel. I reground it to 30 degrees and took it through various grits (I use the Scary Sharp method) up to 1000 grit paper. Now it made clean, long shavings that curled up and away from the plane. The depth stop is still a problem; I’ll probably file off the thick layer of paint on the stop and the area of the plane body where it rests, and maybe roughen the metal up there as well.It’s still not doing everything I need, but it’s cheap, and it does the basics. I’m still planning on spending $250 to get a Veritas Skew Cutting Rabbet Plane when the toy budget allows, but for now this will do. Should you get one? That depends. Are you willing to deal with possibly sending units back until you get a good one? Can you work without a spur cutter, or make your own? Do you know how to grind and sharpen plane blades? In short, are you willing to buy a kit? If so, this can be a workable tool. But I’d recommend looking around for an old (pre-WWII) Stanley or a Record, or better yet, saving your dollars and buying a Veritas.Update: I sold mine and bought a Veritas. Good wood is not cheap, and in a few years the extra $150 that the Veritas cost will be inconsequential.

Cliente de Amazon –

Aunque en la foto presenta un buen terminado, en la realidad esta herramienta está mal diseñada. Para el corte transversal este tipo de cepillo debe tener una pequeña cuña afilada que corta las fibras antes que la hoja afilada haga su función de desbaste, de esa forma se evita que la madera se desgarre. Sin embargo en este cepillo la posición de la cuña esta mal alineada, por lo que no cumple su función. Solo sirve para el cepillado a lo largo de la fibra, es decir solo hace la mitad de las tareas